Struggling to Deliver Better Customer Experience

Manufacturers are increasingly investing into deeper and longer-lasting relationships, even those who have historically relied on a distributor or another third-party to sell their products. Digital has removed this barrier and now empowers manufacturing organizations to be able to connect directly to people who want their products or services. While most understand the importance of setting up their digital selling channels, what is challenging now is knowing how to serve these customers well. The manufacturing industry has predominantly been product-centric rather than customer-focused, thriving on mass production and product efficiency

Henry Ford famously organized his entire business around product standardization, telling his potential “Model T” car buyers, “You can have any colour, as long as it’s black.” Shifting from this long-established mindset to one that revolves around the customer may be difficult for the industry but extremely necessary for future success. These customers will be bringing in their long-established digital expectations from previous interactions with Amazon, Google and other large brands. Meeting these will be no easy feat. However, manufacturers have access to a resource that will be critical in improving customer experiences: data

Data, Data, Data

To drive successful customer experience strategies, manufacturing organizations will need to learn how to take advantage of data. While manufacturers may have access to a plethora of data, having pools of information brings little value if they are unable to transform it to fuel insight-driven strategies. Collecting, uniting and acting on product and customer insights must be a business priority for manufacturers who want to sustain and grow direct relationships with their end customers. If you would like to learn more about data check out our “Why Big Data Is Something You Should Be Paying Attention To.”

Driving Better Customer Experience

How can manufacturers use the insights they’ve collected to serve their customers better? Here are three strategies that will help improve customer experience and drive immense business benefits for manufacturers:

1. Personalizing for the “Segment of One”

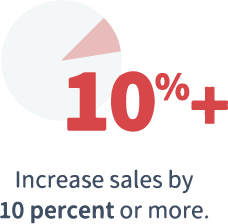

Personalized experiences are creating better and longer lasting customer connections. Customers respond much more positively to one-to-one experiences that span across their entire customer journey, even after their initial purchase. While products can be personalized as well — for example, monograms and customizable text — manufacturers need to start serving the “segment of one”, meaning delivering a tailored customer experience that is fit to the needs of a single customer. Competition for consumers’ attention is already so intense that they will only pay attention to your business if the content and information provided to them is actually relevant to their needs. Well-executed personalization for manufacturers can:

|

|

Personalization not only sets a business apart from other competitors but also encourages customers to make repeat purchases, becoming loyal advocates for the company.

Being able to successfully personalize across different touch points requires businesses to draw from customer data in order to have a single customer view (SCV) that is available to all employees. A successful SCV is created by collecting all information related to your customers and providing a 360-degree view for each person. Different types of data that can be compiled include: browsing activities, sales interactions, firmographics and so forth. Having a single source of truth for your business will be the foundation needed in order to deliver personalized and relevant customer experiences.

2. Implementing New Customer-Focused Business Models

Equip your team members with a greater understanding of your customers so that they can provide better customer service at any point of a customer’s journey. Having teams that are invested into the customer experience is the first step to building a more customer-focused business. Furthermore, data can also be used to transform the manufacturing industry with more customer-centric business models. Specifically, manufacturers are focusing on “servitization” where they extend their product line with implementation, maintenance, upgrades and a lifecycle approach, offering not just a product but an outcome. Through servitization, manufacturers are able to deliver more value to customers by providing a more personal and deeper relationship, while also discovering new streams of revenue for the business. However, in order to integrate servitization into a business model successfully, manufacturers need to have access to insights about their customers and how they interact with their products before useful services or offerings can be added.

Developing Success:

Airbus Helicopters More than 3,000 civilian and military operators rely on Airbus Helicopters to keep their aircraft operational; therefore improving customer experience was critical to the success of the organization. Through their new customer portal, Airbus was able to optimize access to information and services along the entire customer journey. For example, Airbus found an opportunity to enhance customer experience after the sale by informing operators of their helicopters’ health and usage with reports generated from integrated sensors. This is a great first step into further developing new business models that revolve around customer success and can help a business extend customer relationships.

3. Facilitating Innovation

With a better understanding of customers and their needs, organizations are empowered to provide new products and services that customers will need. Identifying these trends will enable manufacturers to stay ahead of their competitors with new offerings that are actually tailored to customer needs and problems instead of innovating simply to keep up with other competitors. Real innovation needs to be driven by a purpose; it needs to be for the customer. With sufficient insights, manufacturers are empowered to explore and create solutions that will actually benefit customers. Ultimately this change will be fuelled by the 4th industrial revolution changing how we simplify the work and are able to put more thought and time to clients.

To drive successful customer experience strategies, manufacturing organizations will need to learn how to take advantage of data.

Your Checklist to Connecting Data in Your Organization

In order to execute better customer experience strategies, manufacturers need to possess the analytical capabilities needed to support these initiatives. Here’s a checklist of functionalities needed in order to successfully implement insight-driven strategies:

Able to Aggregate Data Across Siloed Systems:

Find a solution that is able to aggregate and store data in a centralized location. One of the biggest challenges manufacturers face is they can only use a fraction of the data in their possession due to sprawling legacy systems and siloed databases. Since these older, inoperable platforms cannot connect with each other, data remains separated, hindering a manufacturing organization’s ability to drive targeted campaigns and boost lead generation. The first step is to be able to identify all the different sources of data and being able to bring all of it together into one consolidated platform. Data from multiple sources, connected devices and machinery, channels and other solutions, such as a customer portal, needs to be seamlessly connected in order to build a complete database that manufacturers can draw from. This solution also needs to be able to integrate seamlessly with multiple solutions to be able to deliver better customer experiences with more efficiency and ease. Connecting to other systems such as a digital asset management platform empowers organizations to manage and deliver the right pieces of content.

In the same way, connecting a commerce solution with a data analysis tool can provide insights and information that will improve sales operations and customer experience initiatives.

Able to Provide Actionable Insights:

Now that the data is collected and ready to use, find a tool that possesses machine learning and artificial intelligence capabilities that can find patterns and analyze that data to provide actionable insights. Any application of AI and ML will depend on the quality of the data collected so this functionality needs to follow enhanced data collection. The right tools can easily support data analysis and convert those data points into information that can benefit your business performance, all while accelerating these processes and aiding any data analysts you may have on your team. By developing predictive models, manufacturers will be able to not only draw insights from a vast amount of data but be able to utilize it to improve their customer experience strategies.

Able to Share Data Across the Entire Ecosystem:

In order for these insights to be effective, they must be easily shared and used throughout the business. This becomes especially important for manufacturers that work together with partners, distributors or other members of their digital ecosystem; these insights can benefit all parties and be applied across multiple use cases. Collaboration is especially critical in manufacturing, among partners and distributors. Additionally, the industry has a great need to integrate a network of employees that is distributed in different locations, such as factories, offices or out in the field. One way to execute this is through the use of personalized dashboards, with results and insights that are relevant to specific users and roles. Too often, not enough thought is given to how users will digest the analysis. Determine what the operators, line managers and plant managers need to know and deliver the analysis to each audience in a way that is clear and not cluttered with things they find irrelevant.

Compliant with Data Best Practices:

Regardless of the tools or systems used, best practices need to be set in place. No matter how advanced your tools may be, adding these to failed processes will not magically resolve anything. Establish an agreed-upon framework for gathering, structuring and sharing data so that other departments across the organizations understand how to utilize the information. Keep in mind that the use of customer data for personalized marketing and services will require clear data governance processes and frameworks, especially in light of GDPR and other privacy laws. Additionally, robust roles and permissioning will help restrict access to sensitive customer information and minimize security issues.

While these functionalities are extremely beneficial, simply implementing them will not instantly resolve all customer experience challenges. Manufacturers need to identify how to leverage these tools in conjunction with a strategy tailored to their goals in order to successfully become a customer-focused business. “6 Techniques To Take Data Analysis To Another Level” is another article that may help you get further ahead with your data analysis.

Moving Forward

The manufacturing industry can no longer afford to continue doing business with the same approach Henry Ford had to sell his “Model T” cars. This shift from being product-focused to customer-centric has required manufacturers to collect and leverage data to powerfully understand and serve their individual customers through new customer-focused business models. To find out more about what technologies, anything related to digital experience, can enable success for manufacturers as they implement these new business models, visit our digital transformation page.